In the manufacturing industry, part production costs are one of the top business expenses. When funds are tight, some companies may resort to extreme measures, such as laying off employees or making other significant sacrifices, in an attempt to save money on production costs. However, there are many alternative money-saving options available that won’t negatively impact your business. Below, we will address some of the top money-saving tips for part manufacturers.

Opt for a Manufacturing Process With Low Energy Usage

Aside from labor expenses, energy consumption is one of the highest costs involved in part manufacturing. As such, opting for a manufacturing process that has a comparatively low energy expenditure has the potential to save your business a considerable amount of money.

For example, compared to other injection processes, reaction injection molding (RIM) requires far less heat and pressure to produce complex, durable polyurethane parts. By changing your production process to a more energy-efficient option like RIM, you could greatly reduce your cost of production.

Automate Processes When Possible

Another one of our top money-saving tips for part manufacturers is to automate processes when possible. By automating processes, manufacturers can minimize human error, increase production volume, and enhance product quality. In addition, automating more repetitive processes or hazardous tasks will allow workers to take on more specialized responsibilities. In doing so, companies can optimize their employee’s potential, save on labor costs, and create a safer work environment.

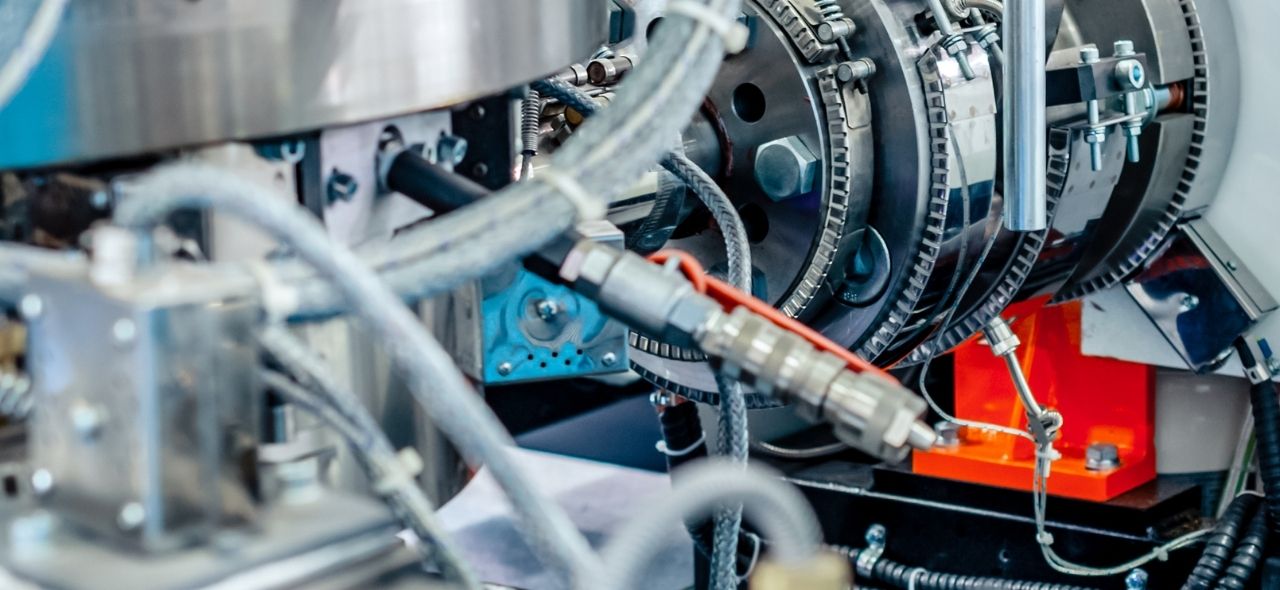

Conduct Proper Equipment Maintenance

Most manufacturing businesses rely on a substantial amount of machinery in order to accomplish their production needs. If such equipment breaks down, the cost of repairs and the money lost due to stalled production can take a significant toll on the business’s finances.

To prevent any machinery problems, it’s important to conduct proper equipment maintenance practices. By regularly inspecting, cleaning, lubricating, and conducting any other necessary maintenance procedures outlined in the equipment’s owner’s manual, you can prevent the significant expenses involved in a premature machinery breakdown.